3D Printing and Bearing Cages

Powering the Bearings Industry

3D Printing for Bearings Cages

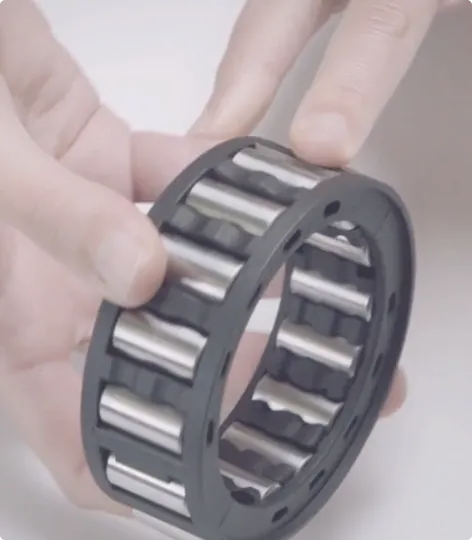

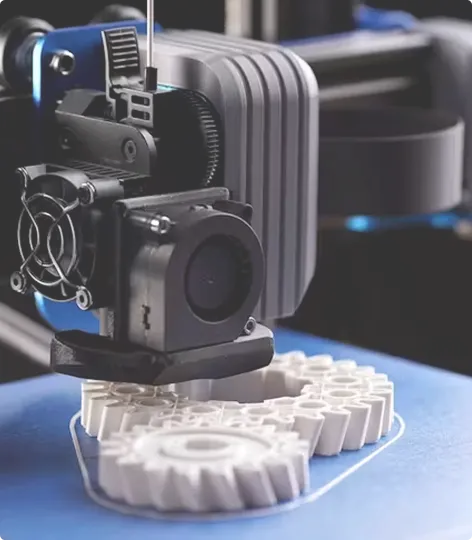

3D printing is reshaping bearing manufacturing by enabling the production of lightweight, high-performance cages with unique material properties and reduced costs.

Bowman 3D, creator of the world’s first 3D-printed split roller bearing cage, delivers rapid, tooling-free production with digital warehousing and no minimum order quantities — combining innovation, flexibility, and precision for modern and legacy bearing needs.

Application focused 3D Printing Solutions

For Bearings Industry

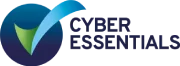

Split Roller Bearing Cages

Innovative designs that provide higher strength-to-weight ratios and lower friction.

Custom & Legacy Bearings

On-demand printing for obsolete or low-volume bearing types without substantial tooling expenses.

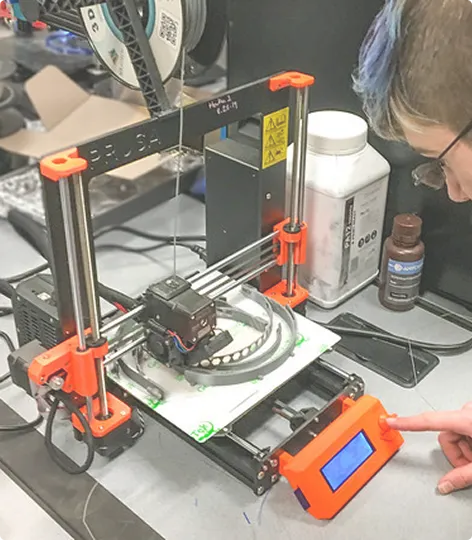

Prototype Bearings

New cage geometries and materials are rapidly developed and tested to optimise performance.

High-Temperature Applications

Components made from innovative polymers that can withstand harsh environments.

Digital Warehousing

Designs are stored digitally and produced as needed, lowering inventory costs and lead times.

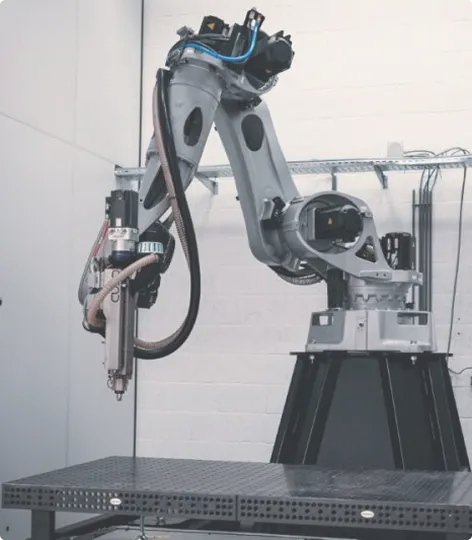

Precision Mass Production

Produces consistent, high-quality output ideal for large-scale bearing component manufacturing.

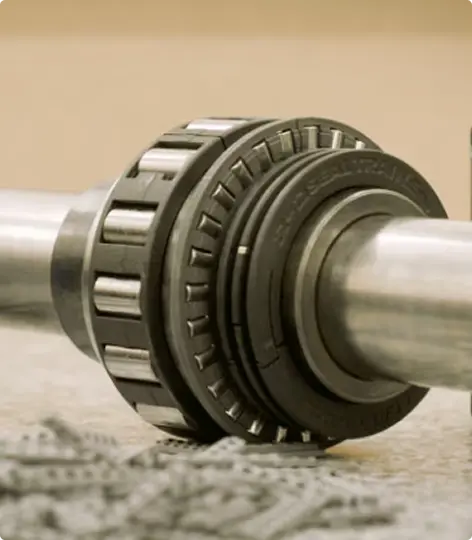

Lightweight alternatives

Replacing typical metal cages with high-performance polymer solutions to reduce inertia.

Connect with Us

Find the Right 3D Printing Solutions Here!

Bowman 3D

10 Isis Court, Wyndyke Furlong, Abingdon, England, OX14 1DZ,

UK