MULTI-JET FUSION

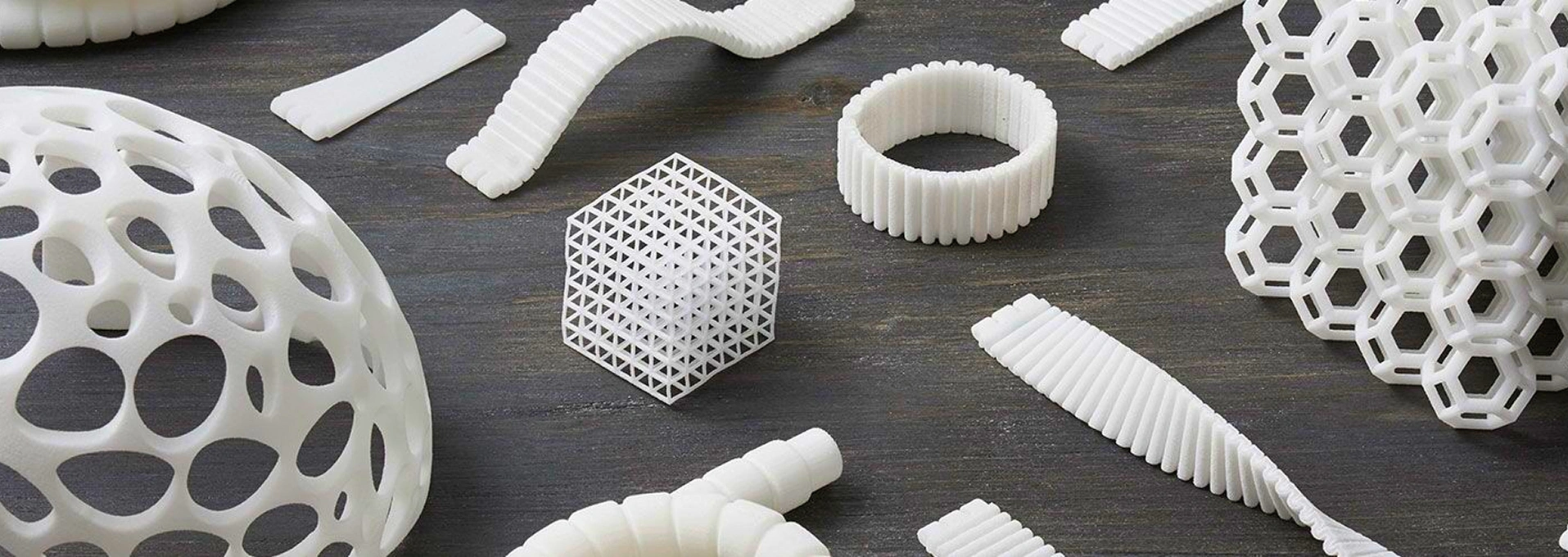

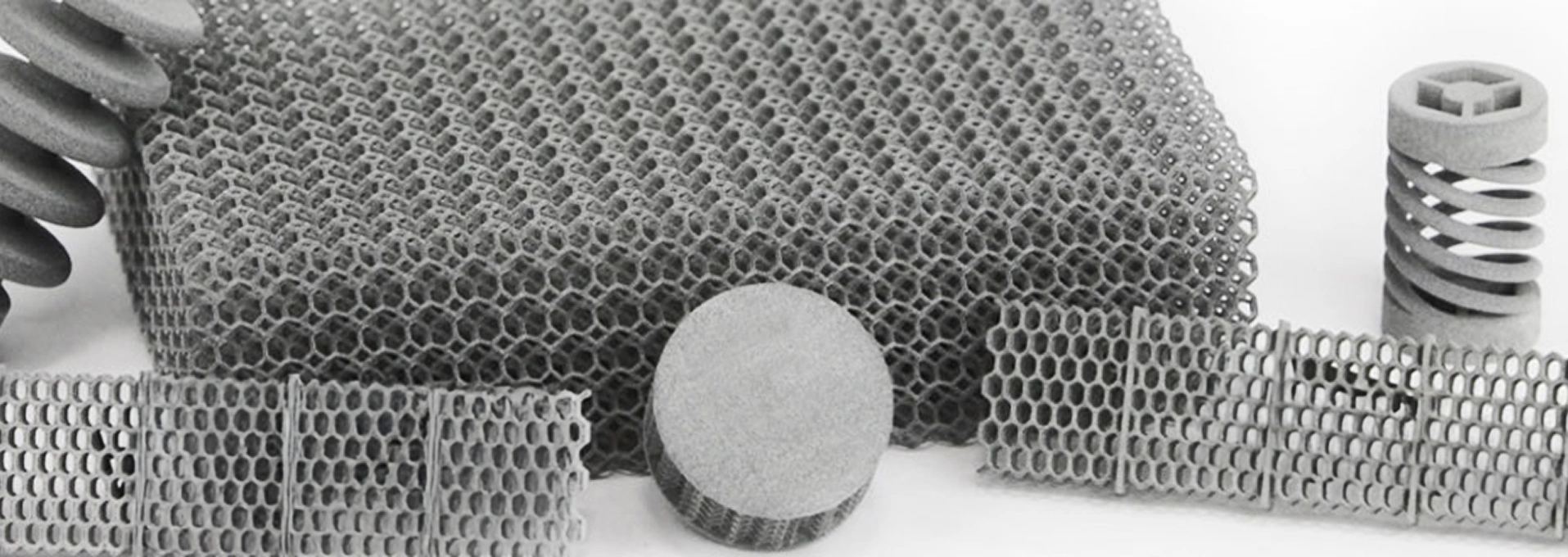

There are many forms of 3D printing - but to be able to economically and reliably produce one to tens of thousands of parts in engineering grade material without detailed hand finishing then powder-bed fusion technologies are the obvious choice.

The Technology

WHAT IS MULTI-JET FUSION?

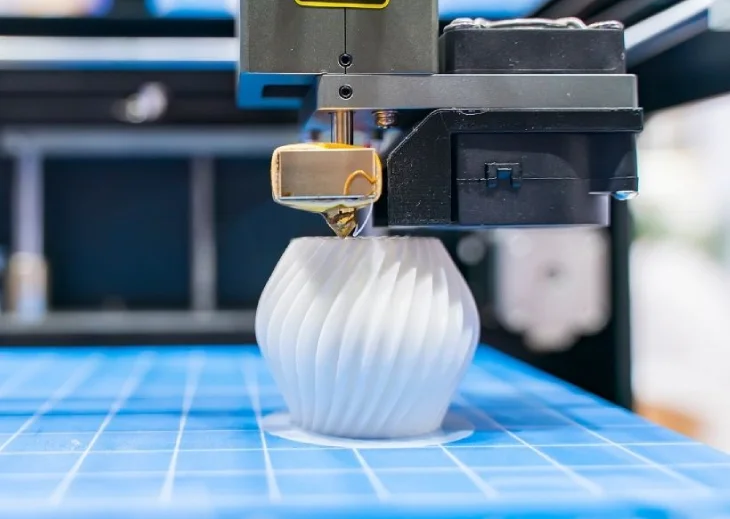

Multi Jet Fusion (MJF) is an HP-patented technology that produces parts similar to the long-established Selective Laser sintering (SLS) technology.

Like SLS it works by adding sequential layers of polymer powder into a build chamber. In contrast to SLS, however, MJF uses a combination of a fusing agent jetted onto the powder surface and a high-powered heat source to selectively fuse areas of each layer together to form parts. Both SLS and MJF can produce high numbers of parts within a single block of powder without needing to incorporate support structures.

The Best Choice for Your Application

WHAT MATERIALS DOES MJF USE?

Surface Finishes

Vibro-Polishing

Out of the printer, parts have a slightly coarse surface. As an additional service, Bowman 3D offers vibro-polishing of parts – using ceramic beads to smooth the surface of parts over a number of hours.

Dyeing

Out of the printer, parts are a neutral shade of gray. Parts can be dyed using black ink.

Vapour Smoothing

A chemical smoothing process that produces a semi-glossy external surface. This process improves the mechanical properties of the part and helps to seal the surface, making it ideal for watertight applications.

Spray Painting

Any colour or gloss level, with several specialist coatings available, including Cerakote.

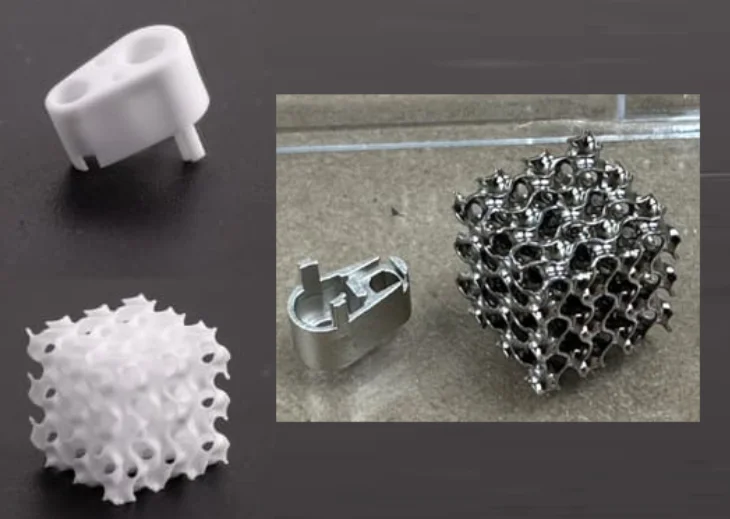

Plating

3D printed parts can be given a thin metal coating to help with conductivity, strength or to produce a specific aesthetic result.

Custom

We have a broad network of industry contacts, as well as in-house expertise, to help us produce a part finished to your desired spec or find the specification you need for your application. Speak to us about non-standard finishes for your project.

Spec Your Parts

Technical Limitations

In addition to general tolerances, thin unsupported parts have a tendency to warp – as parts cool following fusing, less dense parts tend to cool faster which can lead to distortion in parts. This can be reduced or eliminated by thickening parts and altering geometries.

Our Strength

Bowman 3D is a division of Bowman International, a leading innovator of bearings and components. Bowman International has three specialist divisions and one American subsidiary, all united in delivering our mission of genuine innovation, product performance and stock availability.

To read more about Bowman International, visit the Group website.

Did You Know?

One of our key manufacturing processes at Bowman 3D is HP 3D Printing’s Multi Jet Fusion (MJF) technology. These #production3Dprinting machines are perfect for producing parts for a wide range of applications.