PRODUCTION

Turn your prototypes into a full-scale production rollout.

Start Printing

LET’S GET YOUR PARTS PRINTED

Are you confident with your design? Start production this week with Bowman 3D.

Our consultative approach and in-house quality-testing facility means we can implement extensive quality control and testing procedures that ensure your print runs deliver repeatable quality, with short lead times, every time.

Production

A CONSULTATIVE APPROACH AS STANDARD

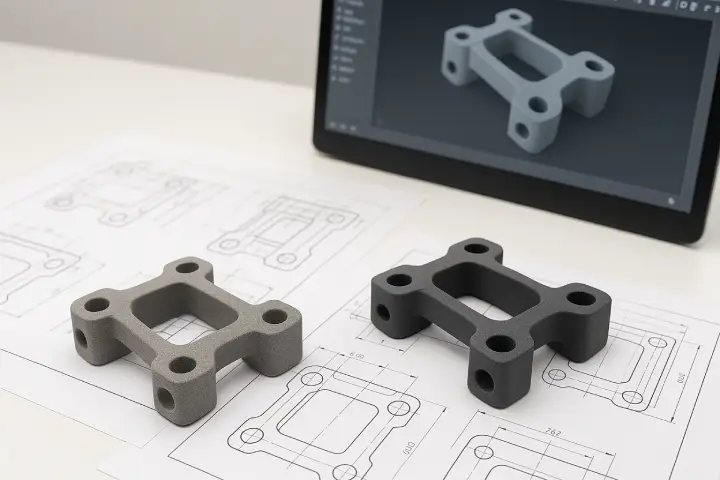

Unlike the common ‘print and post’ services, we will ensure your product is fit for printing, and will work with you to amend your designs before producing your first full batch.

We are experts in leveraging the full design freedoms of 3D printing and will work with you to establish the right quality standards for your markets.

Connect with us to get started.

Email us on 3dsales@bowman.co.uk.

A New Dawn

PRODUCTION 3D PRINTING

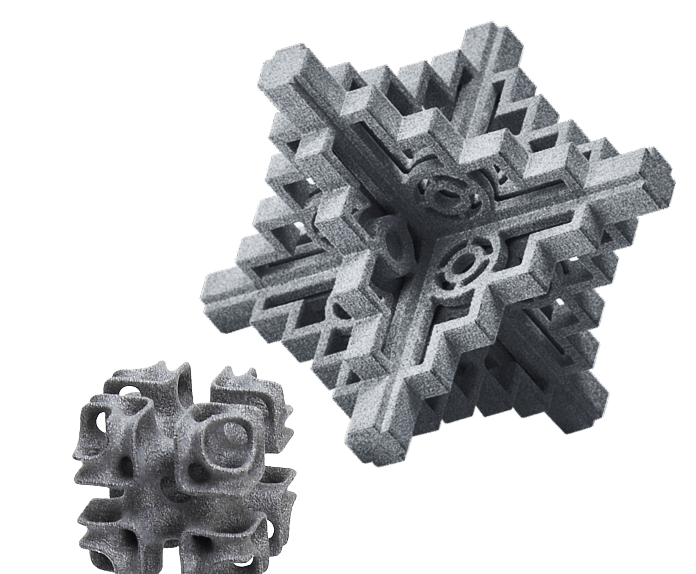

However, its potential as a true production process has only started to be realised within the last decade. With the development of technologies that allow for repeatable production of increasingly large batches of parts, additive manufacturing (as it is otherwise known), is establishing a place among more traditional methods of making components, such as injection moulding and machining. Powder-bed processes, and particularly the HP MJF technology, are very well suited to production of components up to quantities of tens of thousands, depending on part size.

With a good understanding of quality control for the given process, you can order parts with confidence, knowing that they will be supplied to the specified standards. We are keen to share the possibilities of production 3D printing and regularly host visitors to our site, so we can introduce our capabilities in-person. We are also happy to offer educational workshops to support your adoption of the correct process.

Prototyping

READ MORE ABOUT OUR PROTOTYPING SERVICES

Have a query, or Let's get started.

Frequently Asked Questions

3D printing enables flexible, on-demand production without the need for costly moulds or tooling. It allows customisation and small-batch manufacturing at lower costs, ideal for niche or personalised products. Complex designs can be produced as a single part, reducing assembly time and improving performance. The process minimizes material waste and supports lightweight structures, enhancing efficiency and sustainability. It also shortens supply chains by enabling localised manufacturing.

One thing is certain, it will be significantly faster than what you may know of from traditional manufacturing methods. We tend to work in days and weeks rather than months.

However, the true answer will be dependent on the scale and requirements of your project. We can deliver in batches to suit your needs, and because we are part of a component distribution business, we can even stock significant numbers of parts for you, so you have them ready to call off for next day delivery.

Although we can offer an array of technologies for production 3D printing, including FDM and SLA if materials specifications require it, we know that there is one technology that does production better than any other. The best production 3D printing experiences we have are associated with HP’s MJF technology. Production volumes were the reason this technology was invented, and it handles them better than any other additive manufacturing method we have tried.

Again, there are a host of FDM and SLA materials available, and this is the advantage of these technologies. So, if your project has a very specific material requirement that is not available for powder bed technologies, we can often supply it using one of these alternatives.

However, we would direct you towards HP MJF technology wherever viable. We offer our fastest service on our standard production nylon, PA11, but we can also supply PA12 , glass filled PA12, flame retardant PA12, polypropylene and TPU (flexible).

This is ultimately going to be driven by the final application. However, if nylon is a suitable material, we can offer our fastest lead times and most competitive prices on PA11.

We would highly recommend getting in touch with our team who would be very happy to assist. Fill in our contact form, or email 3Dsales@bowman.co.uk to get started.

Get in touch with us (3Dsales@bowman.co.uk). The more we understand about your project and the end application, the better we can tailor our service to suit your needs.

Although the foundation for costs are similar to our prototyping service (space taken up in the build and amount of material required to print the part), production prices are a lot more project-specific. Although the economies of scale do not work in the same way as traditional manufacturing methods (such as injection moulding), large volume orders will benefit from a significant part price discount versus our prototyping service.

We also offer bespoke inspection services and different finishes to suit your needs and these services will have an impact on the final part price.

Take a look at our online quoting portal for a quick cost reference, but bear in mind that production volume prices can look significantly different. Send us your enquiry to get a more accurate customised quote (3Dsales@bowman.co.uk).

Looking for an expert in additive manufacturing?

With a commitment to precision and reliability, we aim to offer a reliable 3D production printing service that meets unique manufacturing needs.